- Home > Application > Automobile

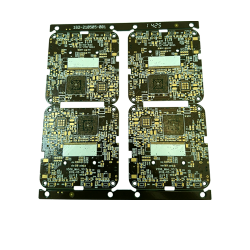

PCE was approved by Tier 1 maker in 2010, and start to do mass-production in 2011. We made over 5,000,000 pieces of PCBs for cars(not included E-Cars) in 2021.

Automotive PCB requires high reliability and durability under harsh environments. In order to sustain with these conditions, the material must pass long-term tests for thermal reliability, moisture absorption, and CAF. Another key factor is the perfection of the through hole plating, it extend the life of the boards.

Where the PCBs Used in Automobiles

ADAS

(Advanced driver assistance system)

ABS

(Anti-lock braking system)

Air Conditioner System

Airbag/SRS

Battery Control System

Dashboard

DC/AC Power Converters

ECU (Engine control unit )

Electronic Mirror/

Window Controls

GPS/Navigation

LED lighting systems

Lidar/ Radar

Multimedia System

Power relays

Steering Control

Transmission Sensors

Electric Vehicle

EV market is the one of the fastest growing market in the world. In 2021, 6.6 million electric vehicles were sold, representing close to 9% of the global car market and more than tripling their market share from two years earlier. All the net growth in global car sales in 2021 came from electric cars.

PCE entry EV supply chain in Q3 2020, and we deliver over 2 million pieces of PCBs to our clients in 2021. We estimate another 15% growth in 2022.